Glentek offers a wide variety of standard options for servo motors and servo drives. However, a custom option is sometimes required. Recently, we designed and built a custom brushless servo motor for an in-house automation project of our own. The project required high speeds and a special shaft for mounting a saw blade.

The motor is used as a spindle motor for cutting small slots into commutators, a part used on all of our DC brush servo motors. Previously, we machined the commutators using a CNC mill with a rotary table. The process worked, but it tied up the machine for long periods of time. To free up the CNC for more intense machining, we built a dedicated commutator slotting machine.

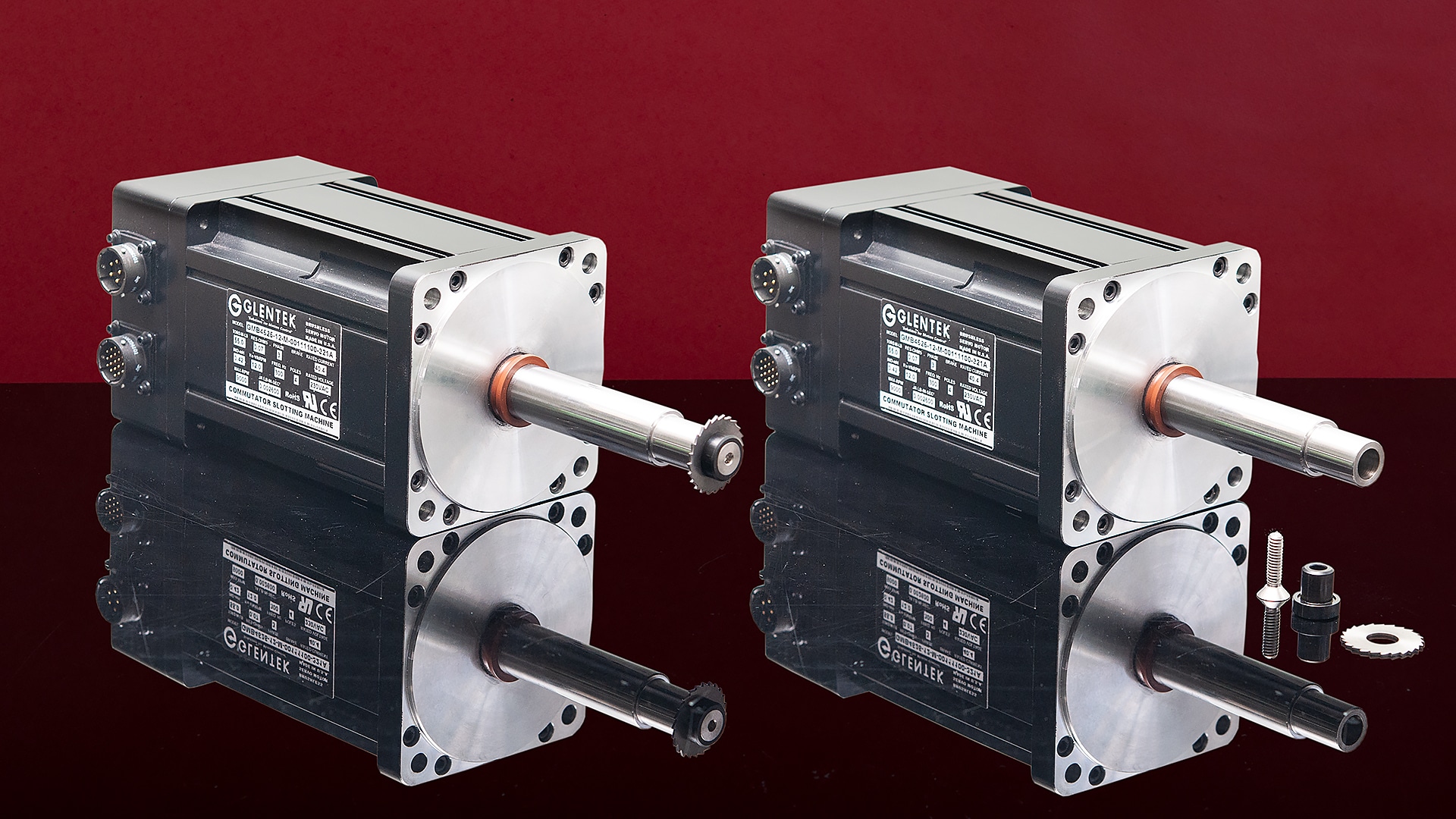

Using a standard motor would have required an assembly of a shaft coupling, saw arbor, arbor cap, and screw to mount the saw blade, with each part adding runout. Our design uses an extended length stainless steel shaft, with a precision counterbore and tapped hole in the end. The saw blade is mounted with just the arbor cap and a screw.

The target tolerance for the width of the slot is .001”, so we needed to simplify the mechanical assembly as much as possible. The counterbore was reamed to +.0005/-.0000” relative to the arbor cap. The final design lets us cut a slot that is just tenths oversize compared to the thickness of the saw blade.

The machine runs off of 120 VAC and the lowest standard BEMF in the desired frame size results in a maximum speed of just under 3000 RPM. We designed a new winding that resulted in a maximum speed of 9000 RPM. This lets us increase the throughput and minimize burrs on the part.

To run at these speeds, shielded, but not sealed bearings were selected and a v-ring seal is used instead of a shaft seal. Both options help reduce the amount of friction in the motor, which is a necessity when running at high RPMs.

If you have an application where you are limited by standard servo motor (or servo drive) options, please contact one of our sales engineers to discuss custom options.